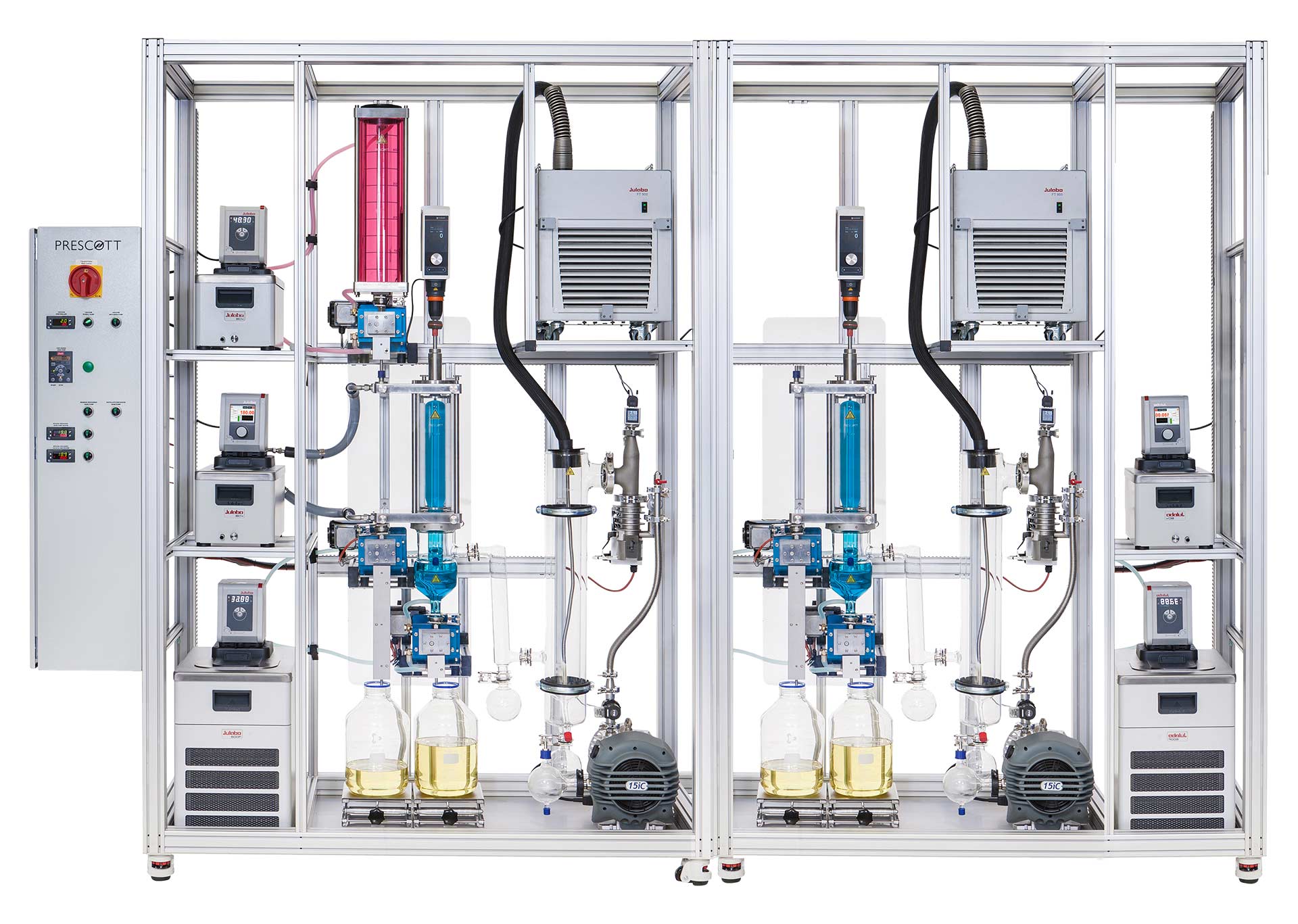

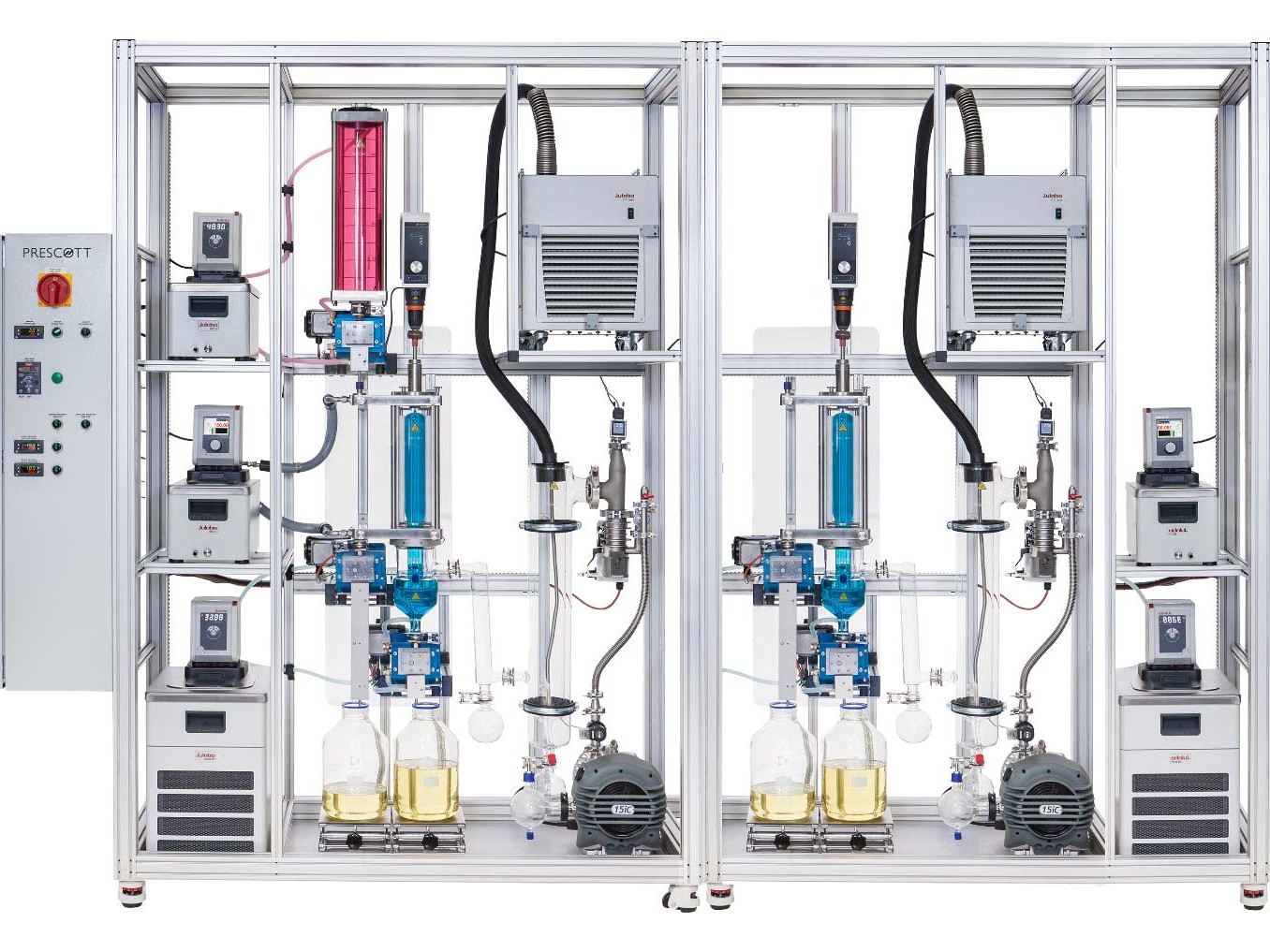

Prescott Distillation: Dual Stage

Simplify production by increasing your distilling capacity to the power of two. Create pure distillate continuously to eliminate production gaps and transfer losses and improve product quality.

The Prescott Dual Stage combines two P1000 units, enabling you to complete successive passes of distilled cannabis materials within a single system, using our proven hybrid evaporator design.

Here’s what else we want you to know about Dual Stage:

- Featuring the high-performance output and ease of use features of the P1000 flagship model, the dual stage is a semi-automated, complete turn-key solution for two-phase distillate production

- An additional gear/transfer pump connects two units to optimize the efficient operation and maximize throughput with minimal labor costs

- Quickly switch between dual-mode and independent, single-mode operation

- Designed for compounds of high viscosity and molecular weight and cannabinoids

- Eliminates the need to run material through the same system twice when creating pure distillate

- Reduces labor needs and avoids gaps in production between batches

- The Dual Stage system can be built to specific UL or CSA standards with a final on-site inspection, and it’s manufactured to universal electrical standards

SYSTEM HIGHLIGHTS

VERTICAL DESIGN

Gravity-enhanced construction helps minimize material loss.

HYBRID EVAPORATOR

Reduce repair and maintenance costs with our patent-pending integrated glass and steel design.

SUCCESSIVE PASSES

Optimize production speed and quality by avoiding gaps between distillation passes.

CONTINUOUS DISTILLATION

Customized heated gear pumps prevent the solidifying of the material within

STREAMLINED CONTROLS

Our universally certified (UL/CUL) control cabinet drives performance with ease.

SCROLL PUMP

Our innovative use of the scroll pump system eliminates solvent without impeding vacuum operation.

VACUUM PRECISION

Dual sensors & a precise digital controller ensure reproducibility between batches.

TEMPERATURE MANAGEMENT

Full-tempered design for maximized surface area optimizes heat transfer.

IMMERSION COOLER

A deep chiller that gets down to -90°C & an enhanced cold trap work to capture volatile

compounds.